Expert Tahoe Instrument Cluster Repair: Mending Precision to Your Gauges

Expert Tahoe Instrument Cluster Repair: Mending Precision to Your Gauges

Blog Article

Ultimate Source for Advanced Car Tool Cluster Fixing Techniques

In the realm of modern auto upkeep, the complexities of tool cluster fixing stand as a vital facet of ensuring the optimum performance of a vehicle (tahoe instrument cluster repair). As modern technology developments, so do the intricacies of these vital parts, requiring a thorough understanding of innovative fixing strategies. With a myriad of possible concerns that can emerge within tool clusters, having a trustworthy resource that supplies in-depth guidance on troubleshooting and rectifying these obstacles becomes vital. By checking out the tools required, common issues encountered, and step-by-step fixing methods, one can outfit themselves with the understanding needed to browse the complex globe of car instrument collection fixing with confidence and precision.

Importance of Advanced Tool Cluster Repair Service

Understanding the relevance of advanced tool collection repair is crucial for keeping the performance and precision of modern lorry systems. The tool cluster acts as the hub of details for motorists, showing critical data such as rate, fuel levels, engine temperature level, and cautioning signs. With the development of modern technology, tool clusters have actually advanced to incorporate complex digital elements and electronic displays, making fixings more elaborate and specialized.

Proper repair service and maintenance of the tool cluster are important for ensuring the security and efficiency of the automobile. Problems with the tool cluster can cause incorrect readings, malfunctions in crucial systems, and safety and security risks when traveling. Advanced instrument cluster repair service strategies entail detecting digital faults, altering sensing units, and reprogramming software application to bring back optimum performance.

Tools and Tools Required

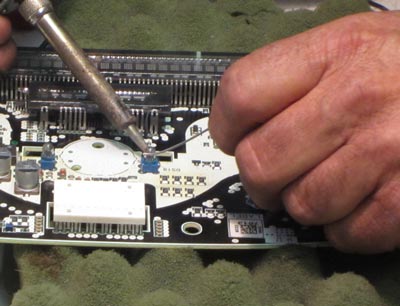

To successfully address the complex repair requirements of modern-day vehicle tool clusters, a specialized set of tools and tools is necessary. Some of the key devices needed for sophisticated vehicle tool cluster repair consist of accuracy screwdrivers, trim removal devices, soldering equipment, digital multimeters, and diagnostic scanners. By having actually these specialized devices and equipment on hand, technicians can properly identify and deal with complex issues in vehicle tool collections.

Common Problems and Solutions

Numerous common issues frequently encountered in vehicle instrument clusters can be efficiently dealt with with targeted remedies. One common issue is defective evaluates, which may arise from a malfunctioning stepper motor. To address this, replacing the stepper electric motor can recover precise gauge readings. Another usual concern is flickering or dim lights on the tool cluster (tahoe instrument cluster repair). This can frequently be connected to a malfunctioning light bulb or bad connections. By changing the light bulb or guaranteeing secure connections, the illumination problem can be quickly treated. Furthermore, a malfunctioning odometer or display screen is a constant worry. This might be as a result of a malfunctioning display unit that requires to be replaced to bring back appropriate capability. Lastly, recurring power or total failure of the instrument cluster may stem from a blown fuse or circuitry concern. Monitoring and changing the fuse, along with examining the wiring for any problems, can help deal with these these details power-related issues efficiently. By recognizing these common issues and applying the proper solutions, automobile tool cluster capability can be brought back effectively.

Step-by-Step Repair Overview

A methodical approach to diagnosing and repairing auto tool collection problems is crucial for achieving reliable and precise outcomes. To begin the repair work process, the very first action is to carefully inspect the tool cluster for any visible damages such as burnt-out bulbs, broken displays, or loosened connections.

Tips for Preventive Maintenance

After carrying out a detailed analysis scan and finishing needed repairs on the auto tool cluster, executing regular preventative upkeep procedures is important to make sure lasting performance and optimum efficiency of the vehicle's vital evaluates and indicators. To start, it is important to regularly examine the tool cluster for any kind of indications of wear, such as fading displays or malfunctioning lights.

Furthermore, upgrading the software application of the tool cluster when essential can guarantee YOURURL.com compatibility with any brand-new features or systems in the automobile. It is additionally suggested to follow the supplier's recommended upkeep schedule and standards for the instrument cluster to keep its longevity. By incorporating these preventative upkeep ideas into your routine car treatment, you can aid prolong the life-span and integrity of your automobile instrument collection.

Verdict

To conclude, sophisticated vehicle instrument cluster fixing methods are necessary for keeping the functionality of contemporary automobiles. By using the appropriate devices and tools, dealing with common problems, and adhering to a detailed repair guide, service technicians can efficiently deal with and detect tool cluster issues. Carrying out preventative upkeep approaches can help extend the life expectancy of the instrument cluster and prevent future issues from occurring.

By checking out the tools needed, usual problems experienced, and step-by-step repair methods, one can outfit themselves with the expertise required to browse the complex globe of vehicle tool cluster repair service with confidence and precision.

A methodical method to identifying and repairing automobile instrument collection concerns is essential for accomplishing reliable and accurate results. By following this detailed overview carefully, car professionals can successfully identify and repair tool collection issues with accuracy and confidence.

In final thought, sophisticated auto tool collection repair service methods are necessary for preserving the functionality of modern-day cars. By using the proper devices and equipment, addressing common concerns, and complying with a step-by-step repair service guide, professionals can successfully identify and deal with instrument cluster issues.

Report this page